-

Product DescriptionCompany Info.<>

- Model:

- GT550

- Processing customization:

- Yes

- Applicable scope:

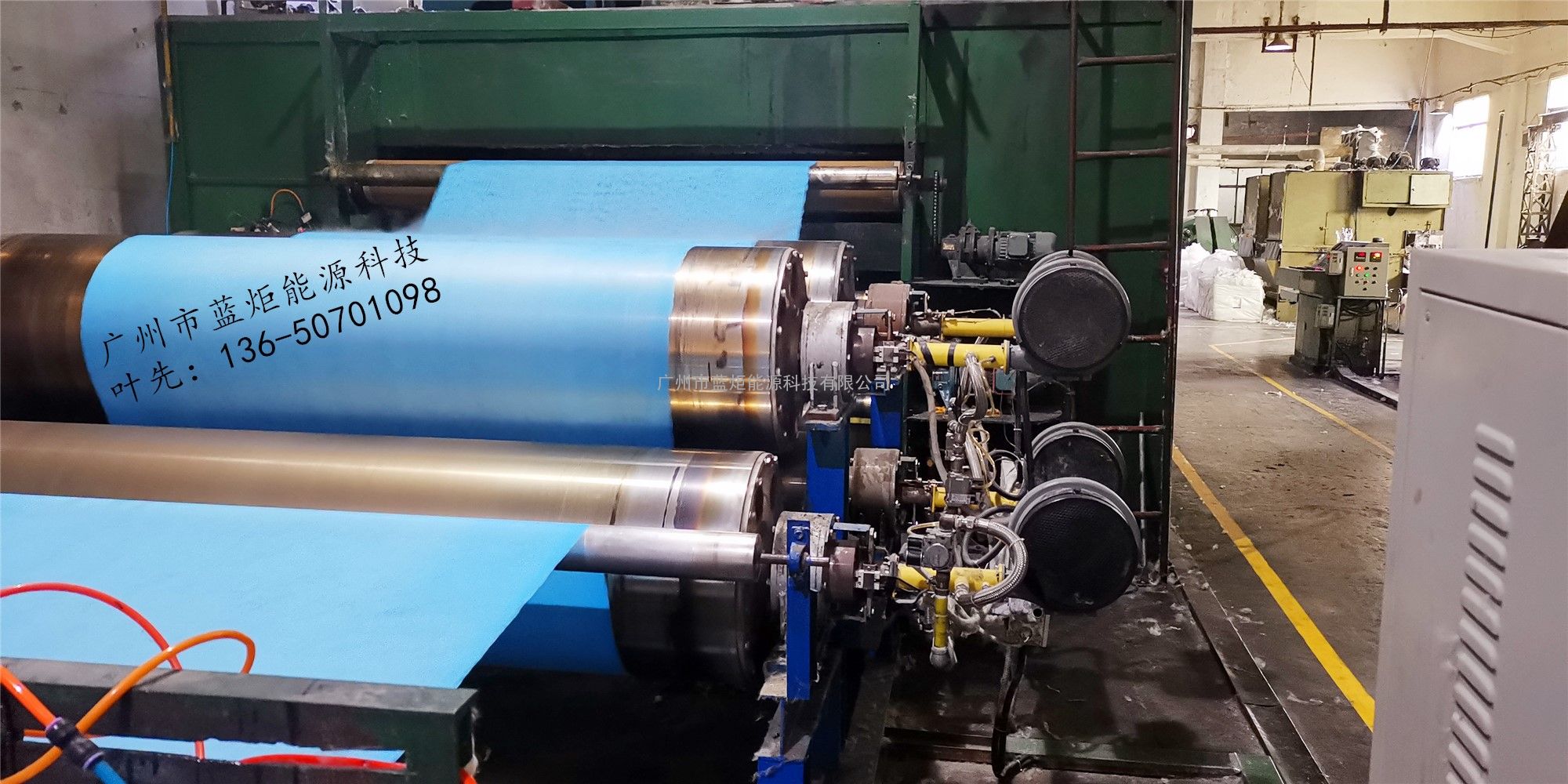

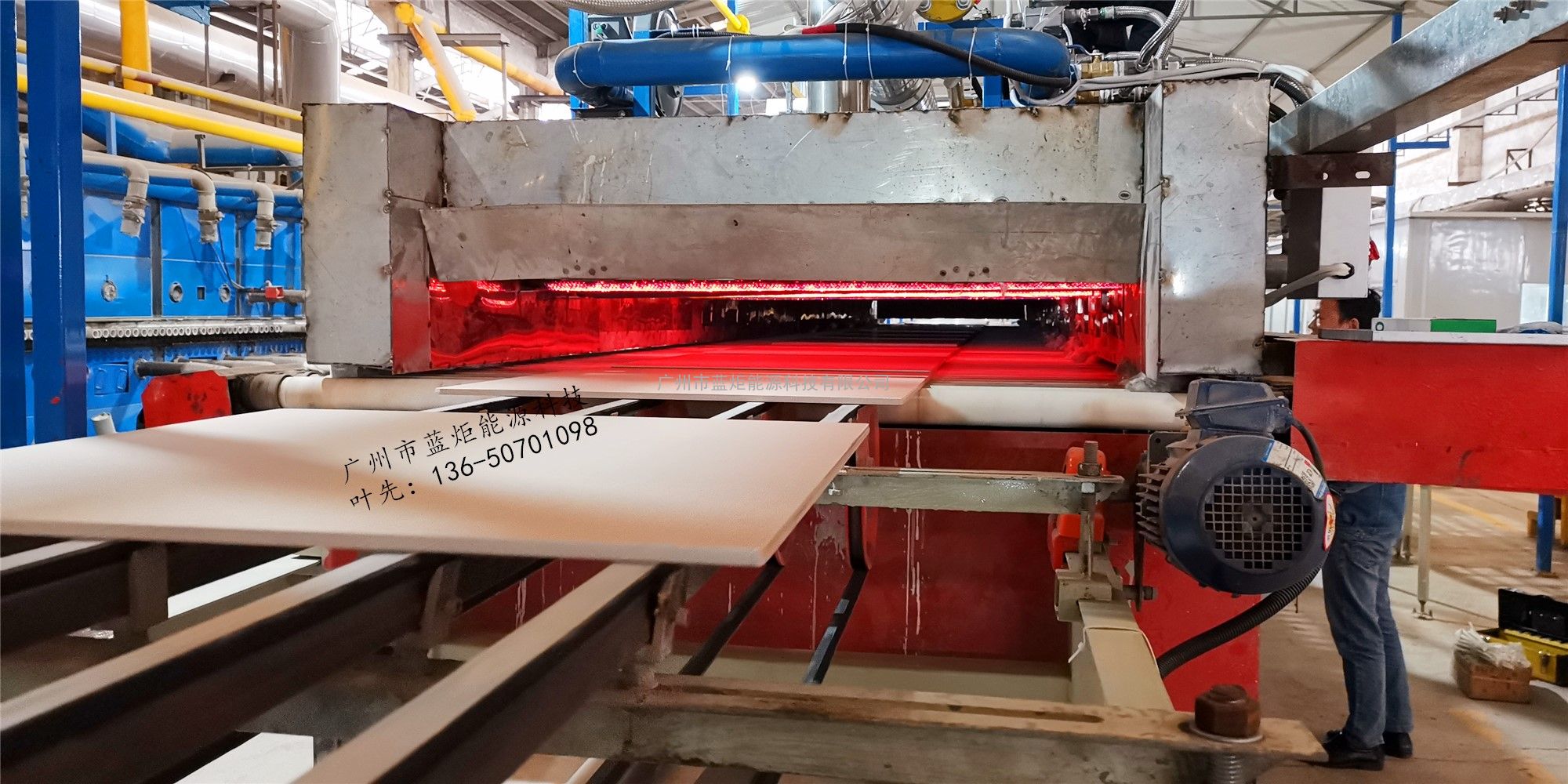

- Paper/Non-woven/Tunnel Furnace

The heat generated by the combustion of gas can raise the temperature of the object to 800- 1000 degrees, thereby radiating intense infrared rays with a corresponding wavelength of 2-4 microns. Infrared is invisible light that travels straight at the speed of light and has a certain penetration. After infrared rays are absorbed by objects, they can be quickly converted into heat energy, so there is a strong heating effect. When the infrared wavelength is consistent with the absorption wavelength of the heated object, the heated object absorbs infrared rays. At this time, the molecules and atoms inside the object resonate to produce strong vibration and rotation. The vibration and rotation raise the temperature of the object and achieve the purpose of heating. Thus, infrared rays can be used for rapid heating.

Advantages of gas infrared drying:

1. Comparison of gas infrared and hot air drying: hot air drying is to dry the surface of the object through the flow of hot air, so that moisture evaporation from the surface, such a way will make the object appear false dry phenomenon (surface dry or crust but not dry inside); infrared drying is through infrared radiation directly to the inside of the object, from inside to outside or inside and outside at the same time absorb radiant energy, so that moisture evaporation, to achieve the purpose of uniform drying inside and outside.

2. Comparison of gas infrared drying and electric drying: electric infrared drying, the principle and gas infrared drying are the same, but electric infrared drying consumes more power. Although electric microwave drying and infrared drying are different, they are also internal and external drying modes, so the drying effect is similar to infrared, but the power consumption is the same as electric infrared. The power of one kilogram of liquefied gas is equivalent to 14 kWh of electricity, and the power of one square meter of natural gas is equivalent to 10 kWh of electricity. According to the electricity price and gas price of each place, it can be obtained that the infrared heating of gas is much more energy-saving than electric heating.

Blue torch infrared equipment energy-saving features:

Because the material is a network of three-dimensional structure of holes, each hole is irregular, coupled with elasticity, so it can effectively avoid airflow noise. At the same time, due to the completely premixed combustion mode, the combustion is sufficient and the excess air coefficient is small, so the thermal efficiency is relatively high and the gas can be saved. Moreover, due to the low resistance of the material, there is no need for a high-power fan, and the resulting electricity bill can be saved.

Due to the use of high temperature resistant alloy material sheets as heating elements and combustion media, and the thermal inertia of the material is small, so it can quickly heat up and cool down, that is, after ignition, its temperature can rise from normal temperature to working temperature within a few seconds. Similarly, after stopping working, it can also cool from working temperature to normal temperature within a few seconds. This is very beneficial to prevent materials from being damaged due to excessive heating, especially to completely avoid flammable materials such as paper, The fabric caught fire due to overheating when encountering extraordinary accidents such as power failure.

product presentation

First, infrared heater radiation principle

According to Boltzmann's law, the relationship between energy and temperature of radiation follows the following formula: E=σ T4Thus, the relationship between energy and temperature of radiation is a fourth-power relationship, that is, the higher the temperature of the object, the greater the energy radiated. The heat generated by the combustion of gas can raise the temperature of the object to 800-1000 ° C, thereby radiating intense infrared rays with a corresponding wavelength of 2-4μ m.

Second, infrared heating (drying) principle

Infrared is invisible light that travels straight at the speed of light and has a certain penetration. After infrared rays are absorbed by objects, they can be quickly converted into heat energy, which has a strong heating effect.

Different materials have different absorption rates for infrared rays. Water is one of the substances that can absorb infrared rays strongly. After water absorbs infrared rays, its temperature rises rapidly and evaporates. This is the principle of infrared drying. Infrared heating is several times faster than conventional hot air heating, so infrared can be used in situations where rapid heating and drying are required.

III. Blue torch gas infrared heating unit

1. The use of fully premixed combustion principle, full combustion, low pollutant emissions.

2. Alloy material as heating element, resistant to mechanical shock and thermal shock, long service life.

3. High radiation temperature and high radiation intensity ensure rapid heating.

4. The special structure ensures a large range of load adjustment and increases flexibility in use.

5. It can be combined into heating equipment of different specifications according to needs, and it is convenient to replace.

6. It can be applied to various occasions requiring heating or drying, such as drying of paper and fabrics, curing of coatings, baking equipment, etc.

IV. Specifications of infrared heater

Shape: 150mm (L)*200mm (W)*40mm (T)

Heating power: 3-25kw

Gas consumption: 0.23-1.95kg/h (liquefied gas) or 0.3-2.5m?/h h (natural gas)

our services

Guangzhou Lanju Energy Technology Co., Ltd. not only has skilled technicians and experienced after-sales service team, but also has many years of practical experience in the field of natural gas combustion, heating and drying. It also keeps up with the trend of applying Internet technology to all aspects of the company's production and operation, actively develops Internet marketing, and timely provides information and technical services for the company's new products. Ensure that users provide perfect services.

pre-sales

1. Guide customers to select the applicable product equipment configuration.

2. According to customer requirements, non-standard customized products, while meeting customer production processes, energy saving and environmental protection.

3. Assign senior engineers to the site for free to plan the site\design and improve the process and scheme.

4. Plan the overall energy use plan according to the customer's on-site energy consumption.

in sale

1. Strict inspection of products before delivery (single machine test is not less than 6 hours).

2. Organize delivery according to contract.

3. Strictly according to the customer to determine the design of manufacturing.

after-sales

1. Assign after-sales service personnel to the site to guide installation and debugging.

2. Train operators on site.

3. Domestic customers encountered problems in the production process, our company's service personnel guarantee to give a clear solution within 12 hours. 48 hours to the scene to deal with.- Name(chinese)

- Name(English)

- Guangzhou City Lanju Energy Technology Co., Ltd

- China credit code

- Identity Verification

- Address

-

Panyu District, Guangzhou, Guangdong, China

- Nearby port

- Guangzhou

Guangzhou City Lanju Energy Technology Co., Ltd. is a high-tech enterprise specializing in the research and development and production of environmentally friendly and energy-saving gas infrared burners, infrared radiators, infrared heating and drying equipment and related products. Its main personnel have more than 10 years of experience in the research and development and management of thermal energy equipment, and owns or has applied for a number of utility models and invention patents. Especially in the field of gas combustion equipment, it is at the forefront of China and at the world-class level. Lanju is committed to providing customers with the most environmentally friendly and energy-saving burners, and creating a better living environment for mankind with humanized products and sincere services. As long as you have any combustion or heating needs, Blue Torch will help you solve them. Blue Torch products have high thermal efficiency, low noise, and pollutant emissions far below national standards. In particular, the NOx control level is in sync with developed countries in Europe and the United States. Blue Torch's strategy is to "focus on the combustion field and participate in international competition." The blue torch will always be a burning torch, leading the direction of environmental protection and energy conservation for mankind. https://yehuang.cn.china.cn/- Name(chinese)

- Name(English)

- Guangzhou City Lanju Energy Technology Co., Ltd

- China credit code

- Identity Verification

- Address

-

Panyu District, Guangzhou, Guangdong, China

- Nearby port

- Guangzhou

Guangzhou City Lanju Energy Technology Co., Ltd. is a high-tech enterprise specializing in the research and development and production of environmentally friendly and energy-saving gas infrared burners, infrared radiators, infrared heating and drying equipment and related products. Its main personnel have more than 10 years of experience in the research and development and management of thermal energy equipment, and owns or has applied for a number of utility models and invention patents. Especially in the field of gas combustion equipment, it is at the forefront of China and at the world-class level. Lanju is committed to providing customers with the most environmentally friendly and energy-saving burners, and creating a better living environment for mankind with humanized products and sincere services. As long as you have any combustion or heating needs, Blue Torch will help you solve them. Blue Torch products have high thermal efficiency, low noise, and pollutant emissions far below national standards. In particular, the NOx control level is in sync with developed countries in Europe and the United States. Blue Torch's strategy is to "focus on the combustion field and participate in international competition." The blue torch will always be a burning torch, leading the direction of environmental protection and energy conservation for mankind. https://yehuang.cn.china.cn/ -

Send your message to this supplier*From:*To:

Mr. ye

*Message:

Mr. ye

*Message:

Copyright © 2003 - 2026 Goepe.com All rights reserved.